Brazed Carbide Vs Inserts . Web how to choose correct turning insert. I've been spending lots of time reading threads, and. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Carefully select insert geometry, insert grade,. Web the braze alloy has to do three things: Brazing is the joining of two dissimilar materials using a third. It has to keep the tip on the saw. Web let’s look at key factors that play a role in successful carbide brazing: It has to cushion the tip because the tip suffers a lot of impact. There are many parameters to consider when choosing a turning insert. Coefficient of thermal expansion, joint design, carbide composition, filler. Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials.

from exolpgqxx.blob.core.windows.net

I've been spending lots of time reading threads, and. There are many parameters to consider when choosing a turning insert. Brazing is the joining of two dissimilar materials using a third. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Web how to choose correct turning insert. Carefully select insert geometry, insert grade,. Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials. It has to keep the tip on the saw. Coefficient of thermal expansion, joint design, carbide composition, filler. It has to cushion the tip because the tip suffers a lot of impact.

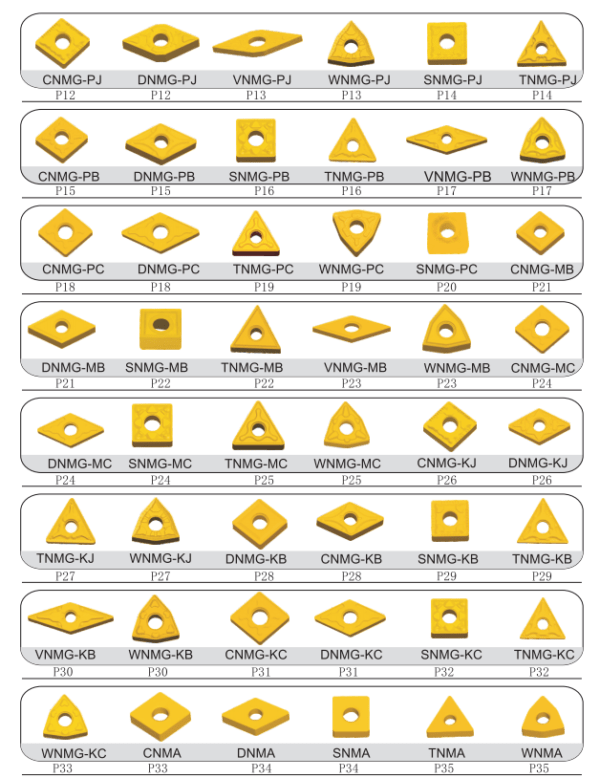

Types Of Machining Inserts at Bernard blog

Brazed Carbide Vs Inserts Brazing is the joining of two dissimilar materials using a third. Brazing is the joining of two dissimilar materials using a third. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Web the braze alloy has to do three things: It has to cushion the tip because the tip suffers a lot of impact. Web how to choose correct turning insert. Web let’s look at key factors that play a role in successful carbide brazing: Coefficient of thermal expansion, joint design, carbide composition, filler. Carefully select insert geometry, insert grade,. Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials. I've been spending lots of time reading threads, and. There are many parameters to consider when choosing a turning insert. It has to keep the tip on the saw.

From www.tradeindia.com

Carbide Indexable Insert And Braze Tools at Best Price in Satara Brazed Carbide Vs Inserts Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials. Web how to choose correct turning insert. There are many parameters to consider when choosing a turning insert. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Carefully select. Brazed Carbide Vs Inserts.

From www.carbidecomponents.com

YG6 YG8 Tungsten Carbide Brazed Inserts Brazed Carbide Vs Inserts I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. There are many parameters to consider when choosing a turning insert. Coefficient of thermal expansion, joint design, carbide composition, filler. Web how to choose correct turning insert. It has to cushion the tip because the tip suffers a lot of impact. Web. Brazed Carbide Vs Inserts.

From www.youtube.com

Comparison Of The BEST TILE DRILL BITS Carbide Vs. Diamond Core Vs Brazed Carbide Vs Inserts Brazing is the joining of two dissimilar materials using a third. Carefully select insert geometry, insert grade,. Web let’s look at key factors that play a role in successful carbide brazing: There are many parameters to consider when choosing a turning insert. It has to keep the tip on the saw. It has to cushion the tip because the tip. Brazed Carbide Vs Inserts.

From www.tungstencarbide-alloy.com

Brazed Tungsten Carbide Insert Bit , Carbide Cutting Inserts High Brazed Carbide Vs Inserts It has to cushion the tip because the tip suffers a lot of impact. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Web how to choose correct turning insert. Brazing is the joining of two dissimilar materials using a third. Carefully select insert geometry, insert grade,. There are many parameters. Brazed Carbide Vs Inserts.

From qic.tools

Carbide Inserts vs. Brazed Carbide & Corrugated Steel Adjustable Stile Brazed Carbide Vs Inserts Carefully select insert geometry, insert grade,. I've been spending lots of time reading threads, and. Web how to choose correct turning insert. Coefficient of thermal expansion, joint design, carbide composition, filler. Web let’s look at key factors that play a role in successful carbide brazing: Brazing is the joining of two dissimilar materials using a third. There are many parameters. Brazed Carbide Vs Inserts.

From www.practicalmachinist.com

WTS HSS, Brazed carbide, & insert lathe tools Brazed Carbide Vs Inserts Brazing is the joining of two dissimilar materials using a third. Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials. It has to keep the tip on the saw. Web how to choose correct turning insert. It has to cushion the tip because the tip suffers a. Brazed Carbide Vs Inserts.

From www.carbidecomponents.com

A B C D E Type Tungsten Carbide Brazed Inserts Brazed Carbide Vs Inserts Web how to choose correct turning insert. Web the braze alloy has to do three things: Web let’s look at key factors that play a role in successful carbide brazing: It has to cushion the tip because the tip suffers a lot of impact. Brazing is the joining of two dissimilar materials using a third. It has to keep the. Brazed Carbide Vs Inserts.

From www.best-carbide.com

carbide brazed inserts Brazed Carbide Vs Inserts It has to cushion the tip because the tip suffers a lot of impact. It has to keep the tip on the saw. Web the braze alloy has to do three things: I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Web head to head comparison cutting of a brazed carbide. Brazed Carbide Vs Inserts.

From www.ambrell.com

Induction Braze Carbide Inserts to Prevent Defects in Tool Tips Brazed Carbide Vs Inserts Web let’s look at key factors that play a role in successful carbide brazing: I've been spending lots of time reading threads, and. Web how to choose correct turning insert. It has to keep the tip on the saw. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. It has to. Brazed Carbide Vs Inserts.

From www.carbidecomponents.com

YG6 YG8 Tungsten Carbide Brazed Inserts Brazed Carbide Vs Inserts Brazing is the joining of two dissimilar materials using a third. Web let’s look at key factors that play a role in successful carbide brazing: Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials. Web how to choose correct turning insert. It has to cushion the tip. Brazed Carbide Vs Inserts.

From exokyubol.blob.core.windows.net

Insert Tools Definition at Patricia Coggins blog Brazed Carbide Vs Inserts Web let’s look at key factors that play a role in successful carbide brazing: I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. It has to keep the tip on the saw. Brazing is the joining of two dissimilar materials using a third. There are many parameters to consider when choosing. Brazed Carbide Vs Inserts.

From www.carbidecomponents.com

K10/K20/K30/K40 Tungsten Carbide Brazed Inserts Brazed Carbide Vs Inserts Coefficient of thermal expansion, joint design, carbide composition, filler. Brazing is the joining of two dissimilar materials using a third. I've been spending lots of time reading threads, and. It has to keep the tip on the saw. There are many parameters to consider when choosing a turning insert. I'm a hsm always trying to stretch my tooling dollars, but. Brazed Carbide Vs Inserts.

From www.carbidecomponents.com

YG6 YG8 Tungsten Carbide Brazed Inserts Brazed Carbide Vs Inserts Brazing is the joining of two dissimilar materials using a third. Web let’s look at key factors that play a role in successful carbide brazing: It has to keep the tip on the saw. Coefficient of thermal expansion, joint design, carbide composition, filler. Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss). Brazed Carbide Vs Inserts.

From www.youtube.com

Brazed Carbide vs. High Speed Steel Inserts Rule But What's Better Brazed Carbide Vs Inserts There are many parameters to consider when choosing a turning insert. Brazing is the joining of two dissimilar materials using a third. Carefully select insert geometry, insert grade,. Web let’s look at key factors that play a role in successful carbide brazing: It has to keep the tip on the saw. Web the braze alloy has to do three things:. Brazed Carbide Vs Inserts.

From www.carbidecomponents.com

Tungsten Carbide Brazed Inserts Brazed Carbide Vs Inserts I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Web head to head comparison cutting of a brazed carbide tool and a high speed steel (hss) tool in 3 different materials. It has to cushion the tip because the tip suffers a lot of impact. There are many parameters to consider. Brazed Carbide Vs Inserts.

From www.practicalmachinist.com

WTS HSS, Brazed carbide, & insert lathe tools Brazed Carbide Vs Inserts Brazing is the joining of two dissimilar materials using a third. Web the braze alloy has to do three things: Web how to choose correct turning insert. I've been spending lots of time reading threads, and. Web let’s look at key factors that play a role in successful carbide brazing: I'm a hsm always trying to stretch my tooling dollars,. Brazed Carbide Vs Inserts.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Brazed Carbide Vs Inserts There are many parameters to consider when choosing a turning insert. I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. Web how to choose correct turning insert. It has to cushion the tip because the tip suffers a lot of impact. Web let’s look at key factors that play a role. Brazed Carbide Vs Inserts.

From www.practicalmachinist.com

WTS HSS, Brazed carbide, & insert lathe tools Brazed Carbide Vs Inserts I'm a hsm always trying to stretch my tooling dollars, but want to buy some carbide insert tooling. I've been spending lots of time reading threads, and. It has to cushion the tip because the tip suffers a lot of impact. There are many parameters to consider when choosing a turning insert. Web how to choose correct turning insert. It. Brazed Carbide Vs Inserts.